T1 & T2 Product Transfers Systems

Smart Transfer Systems for Seamless Product Flow Between Processing StagesProduct Transfer Systems are modular units designed to move, distribute, and guide product flow from upstream processes to downstream packaging machinery.

The Bessen T1 and T2 Product Transfer Systems are designed to ensure efficient, accurate, and hygienic movement of bulk and unit products between different stages of your production line. Bessen offers tailored solutions to fit your process requirements, product types, and facility layout. Built entirely from stainless steel and engineered for integration with upstream and downstream equipment, these systems improve overall line performance while maintaining sanitary design standards essential for food, pharma, and industrial environments.

T1 Product Transfer System:

The Bessen T1 Product Transfer System is built for high-capacity operations requiring precise multi-lane product distribution. With a modular stainless-steel frame, motorized diverters, and optional weigh-check integration, the T1 supports flexible layouts and hygienic operation, making it ideal for industrial packaging lines with thermoforming equipment.

T2 Product Transfer System:

The Bessen T2 Product Transfer System is versatile solution designed for non-thermoforming applications. It’s ideal for two-lane setups handling free-flowing materials like nuts, powders, and more. With its space-saving design, gravity or vibratory feed options, and open-frame stainless steel construction, the T2 is perfect for production environments that require flexibility and hygiene without the need to support thermoformers.

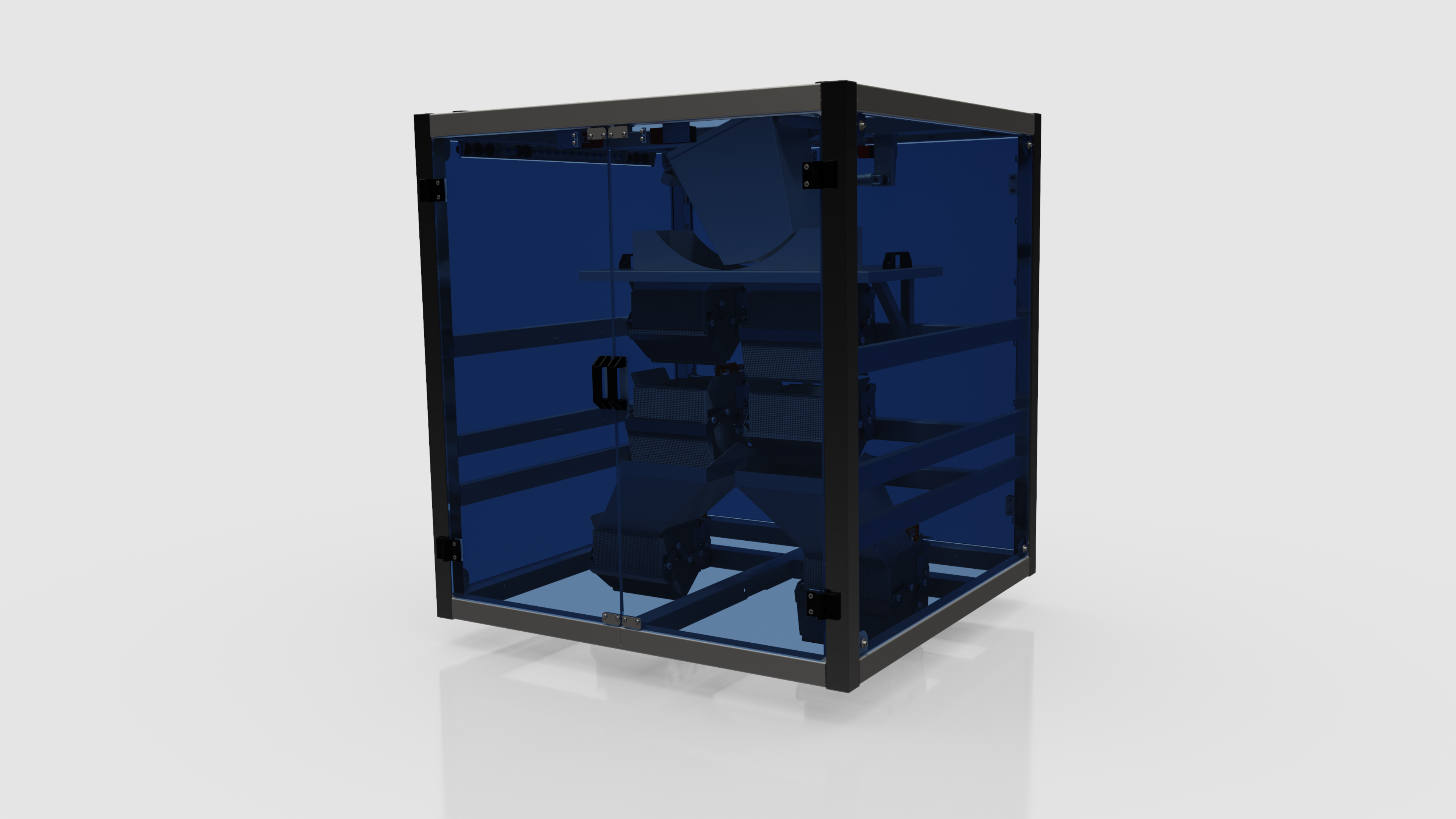

BESSEN T1 Product Transfer System

BESSEN T1 Product Transfer System

The Bessen T1 Product Transfer System is specifically designed to support high-capacity thermoforming lines with four or more buckets. Built for consistent, multi-lane distribution of powders, granulates, snacks, and similar products, the T1 system ensures accurate product flow.

Crafted from food-grade stainless steel, the T1 system features modular construction, motorized diverters, and optional weighing integration for precise control and cleanability. Whether feeding a multi-bucket thermoformer or distributing product into form-fill-seal machines, the T1 provides scalable, sanitary, and high-performance product transfer.

Key Features:

MULTI-LANE OUTPUT DISTRIBUTION (4+ BUCKETS):

Designed to divide and route product evenly into four or more buckets on a thermoforming machine, enabling synchronized high-speed operation.SERVO OR PNEUMATICALLY CONTROLLED DIVERTING GATES:

Each lane is equipped with independently actuated flaps or gates, allowing precise control over product release into each bucket, reducing waste and ensuring accuracy.STAINLESS STEEL SANITARY DESIGN:

The frame and product-contact surfaces are made of food-grade stainless steel, suitable for strict hygiene requirements in food or nutraceutical packaging.FULL SAFETY ENCLOSURE WITH VISIBILITY:

Transparent side panels offer protection and allow operators to monitor product flow and gate activity in real time.MAINTENANCE-FRIENDLY CONFIGURATION:

Hinged access doors and a modular frame simplify cleaning and servicing, minimizing downtime during product changeovers or sanitation procedures.INTEGRATED CONTROL SYSTEM:

The machine is operated through a dedicated control panel, offering programmable feeding cycles, synchronization with thermoformer signals, and real-time diagnostics.

Ideal For:

- 4+ BUCKET THERMOFORMING SYSTEMS

- DRY PRODUCTS SUCH AS SNACKS, POWDERS, SEEDS, PET FOOD

- LARGE-SCALE OR CONTINUOUS OPERATION PACKAGING LINES

- HIGH-SPEED FORM-FILL-SEAL ENVIRONMEN

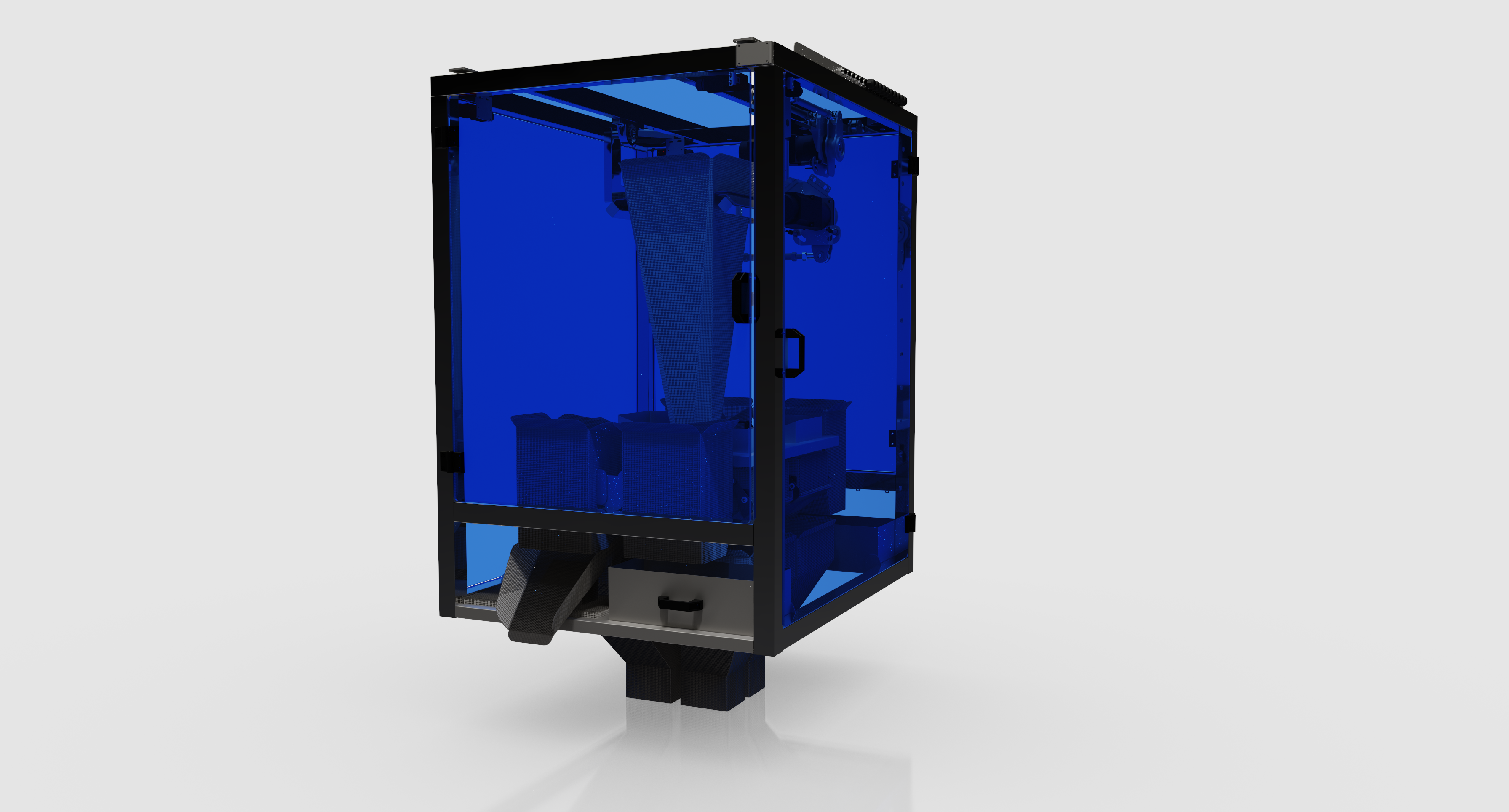

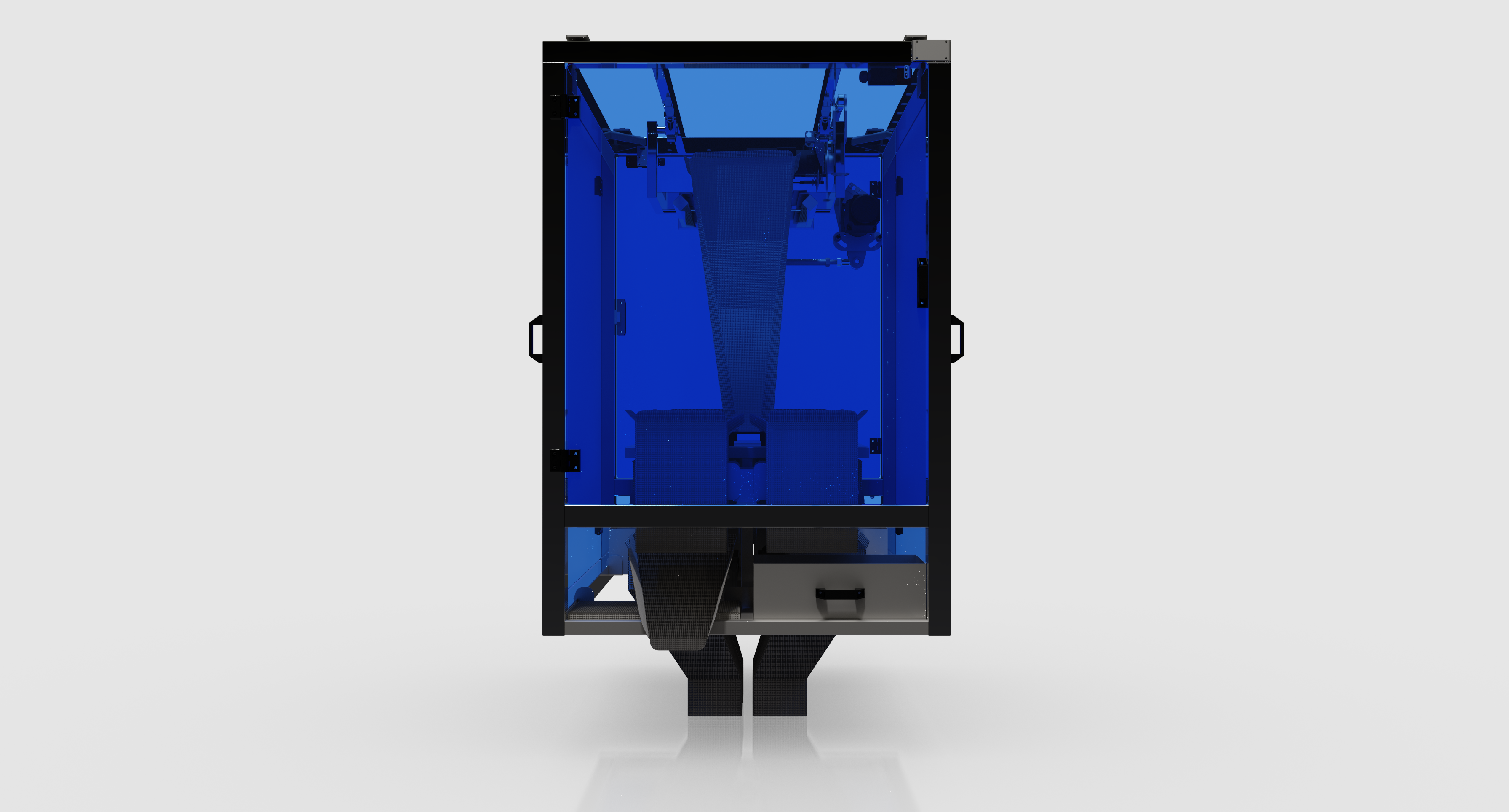

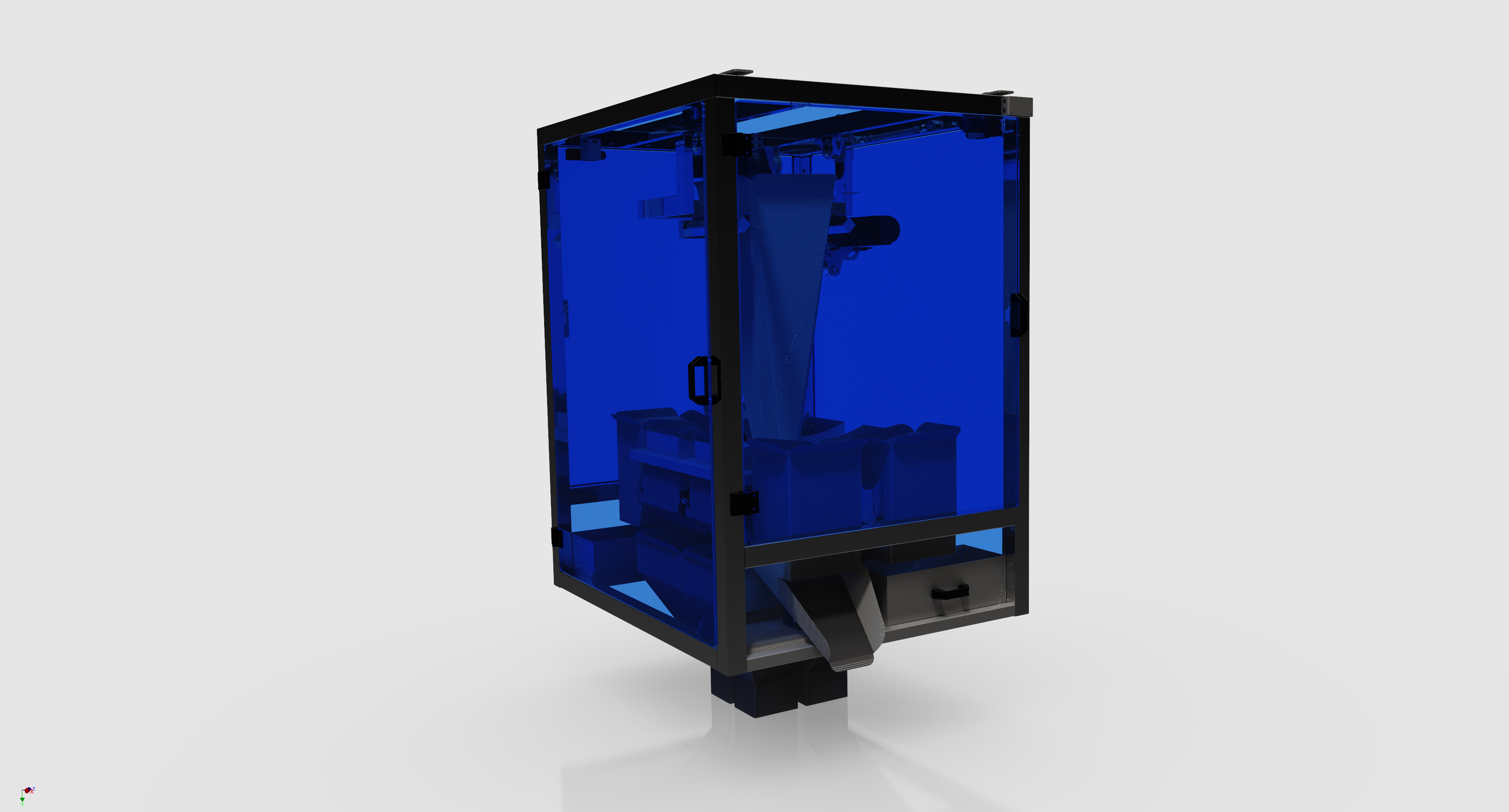

BESSEN T2 Product Transfer System

BESSEN T2 Product Transfer System

The Bessen T2 Product Transfer System is a flexible solution for packaging setups that do not require thermoforming. Ideal for directing dry product flow into baggers, weighers, or manual stations, the T2 is engineered for free-flowing materials such as nuts, powders, seeds, and small particulates.

With options for gravity-fed or vibratory transfer, the T2 system combines hygienic stainless-steel design with minimal maintenance and quick cleaning. It is the perfect choice for any application where simplicity, speed, and sanitation are key.

Key Features:

- TWO-LANE PRODUCT DISTRIBUTION:

Engineered to split product streams into two synchronized channels, the T2 ensures uniform feeding into non-thermoforming systems. - ACTUATED DIVERTING GATES:

Internal diverters regulate material flow via servo or pneumatic control, allowing precise timing and balanced discharge. - FOOD-GRADE CONSTRUCTION:

Built with a stainless-steel frame and smooth internal surfaces for optimal hygiene, even in intensive industrial environments. - TRANSPARENT SAFETY HOUSING:

Equipped with polycarbonate doors, the unit ensures operator safety while maintaining full visibility of the product path. - CLEANING & ACCESSIBILITY:

Modular layout and hinged doors provide easy access for cleaning and maintenance, supporting sanitation in multi-shift facilities. - CONTROL INTERFACE:

A user-friendly panel offers full control over gate timing, diagnostics, and integration with upstream mixers or dosing systems.

Ideal For:

2-BUCKET NON-THERMOFORMING PACKAGING SYSTEMS

FREE-FLOWING DRY PRODUCTS (SEEDS, POWDERS, NUTS, GRANULES)

LARGE-SCALE OR MODULAR LINES WITHOUT THERMOFORMING

OPERATIONS REQUIRING PRECISE SPLIT-FEED PRODUCT HANDLING