VFFS Machines & Bagging Machines

BESSEN Vertical Form Fill and Seal Machines: Versatile Solutions for Diverse Bag Styles and High-Speed Production NeedsBessen Vertical Form Fill and Seal (VFFS) Machines are cutting-edge automatic packaging systems designed to deliver precision, efficiency, and versatility for a variety of packaging applications. Engineered for high-speed operation and seamless performance, Bessen VFFS machines are the perfect solution for businesses in industries such as food packaging, pharmaceuticals, and consumer goods.

With the ability to handle a wide range of film types and bag styles, including pillow bags, gusset bags, flat-bottom bags, and 4-way seal bags, these machines offer unmatched adaptability. Advanced features like Modified Atmosphere Packaging (MAP) flushing, vacuum film assist, and tear notch customization ensure your products are securely packaged and maintain their quality.

Bessen VFFS machines integrate effortlessly with various filling systems, such as combination scales, linear scales, and auger fillers, making them an ideal choice for businesses aiming to streamline their packaging process and increase production efficiency.

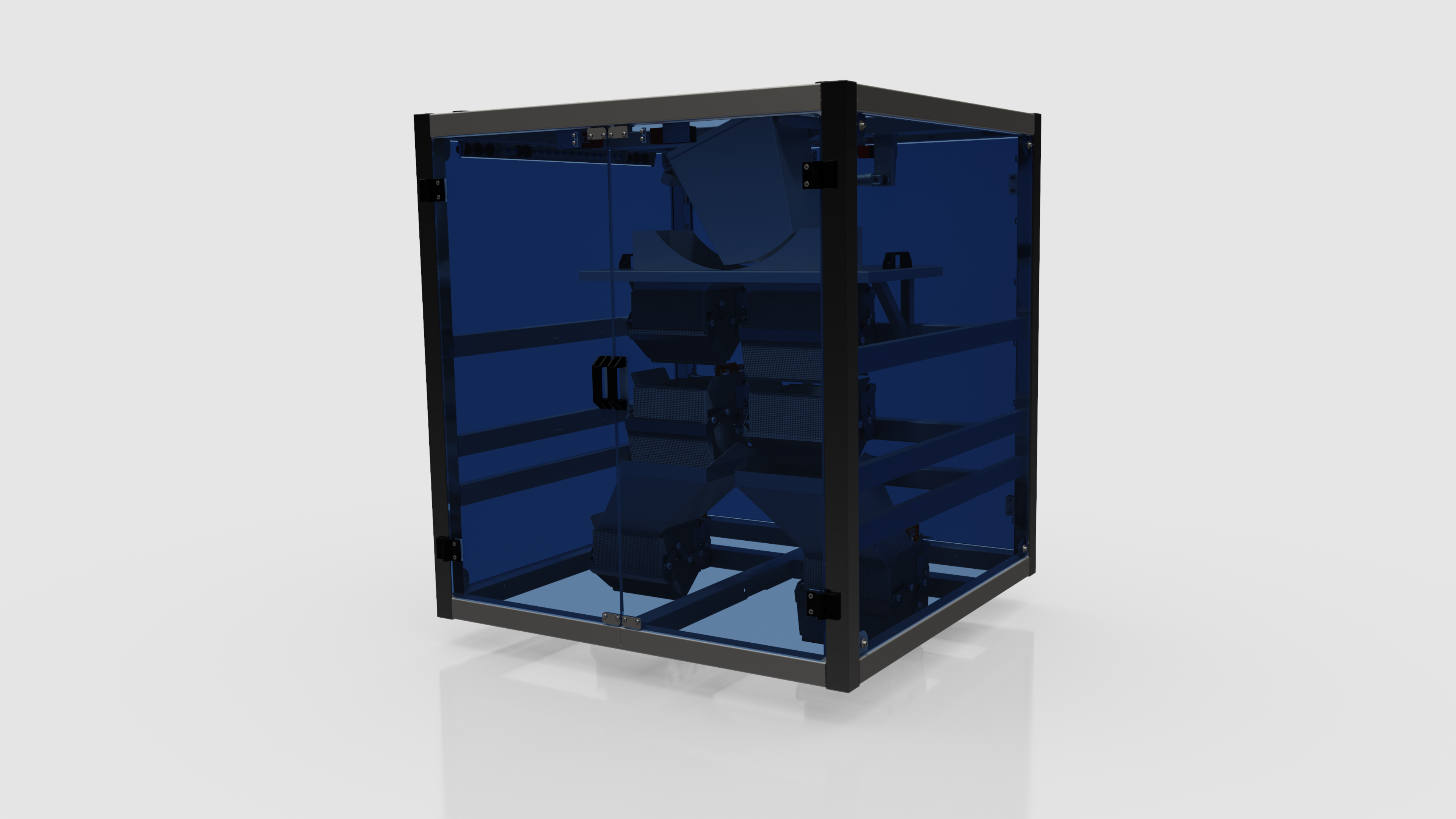

V1000 Series Vertical Form Fill and Seal (VFFS) Machines

BESSEN V1000 Series Vertical Form Fill & Seal (VFFS) Machines: Your Solution for Versatile Bagging Options

Bessen Vertical Form Fill & Seal (VFFS) Machines are the ultimate solution for businesses seeking versatility in bagging solutions. The V1000 Series offers a wide range of bag types, sizes, shapes, and styles, making it ideal for industries such as food packaging, pharmaceuticals, and consumer goods. Equipped with innovative functions and customizable options, these machines are designed to meet your specific packaging requirements.

Ease of Use:

Bessen VFFS machines feature an intuitive user-friendly interface, enabling operators to:

- Quickly change programs

- Save and load up to 30 preset parameters

- Seamlessly switch between various bag styles and products

This functionality reduces changeover times and maximizes production efficiency, ensuring smoother operations for high-demand environments.

Quality Assurance:

Our state-of-the-art plastic tracing technology ensures precise film movement control, resulting in consistently high-quality seals, including the center seal. This advanced feature guarantees dependable and durable packaging, tailored to your specific industry needs. Bessen VFFS machines are your go-to solution for reliable, versatile, and efficient packaging systems, enhancing your production line while maintaining superior quality.

Optimal Fetchers

- Gusset device

- Hanging hall punching device

- Gas flashing

- Air removal

- Air expelling

- PE film sealing

- Seal cooling

- Vibrating

- Easy tear

- Bag support

Application

- Vegetables

- Frozen pasta

- Frozen vegetables

- Fresh pasta

- Dry product

- Powder product

- Liquid product

- Creamy liquids

- Chemical products

Filling application:

- Combination weigher

- Linear weigher

- Cup measuring device

- Auger filler

- Liquide filler (pneumatic)(servo)

Film Width – 5.5” to 28”

Bag Size – L * W (2.25” ~ 20”) * (2.5” ~ 13.75”)

Max Speed – 100 Bags/min (depending on bag size)

Power – 208~240V 1phase 60Hz 5.5KW

HMI – 7” or 9.7″ HMI Touch Screen

Drive System – 1 or 2 Servo Motors

Gross Weight – 1400LB

V2000 Series Vertical Form Fill and Seal (VFFS) Machines

BESSEN V2000 Series Vertical Form Fill & Seal (VFFS) Machines: Packaging Solutions for Diverse Bag Types

Bessen V2000 Series Vertical Form Fill & Seal (VFFS) Machines deliver innovative and versatile packaging solutions tailored to accommodate a wide variety of bag types, sizes, shapes, and styles. Designed for industries like food packaging, pharmaceuticals, and consumer goods, these machines offer unmatched customization to meet your unique packaging needs.

Ease of Operation:

Bessen’s VFFS machines feature a user-friendly interface that simplifies operation. Key features include:

- Effortless program modifications

- The ability to save and load up to 30 preset parameters

- Quick transitions between different bag styles and product types

These capabilities significantly reduce changeover times and improve production efficiency, making the V2000 Series ideal for high-demand environments.

Quality Control:

Equipped with advanced plastic tracing technology, the V2000 Series ensures precise film movement control for consistently superior seals, including the center seal. This technology guarantees reliable, high-quality packaging for every production cycle.

Why Choose Bessen V2000 Series?

The Bessen VFFS machines provide robust, reliable, and highly customizable solutions, enhancing your packaging line with efficiency, precision, and dependability. Whether you’re packaging pillow bags, gusset bags, or flat-bottom bags, the V2000 Series adapts to your needs while delivering exceptional results.

Optimal Fetchers

- Gusset device

- Hanging hall punching device

- Gas flashing

- Air removal

- Air expelling

- PE film sealing

- Seal cooling

- Vibrating

- Easy tear

- Bag support

Application

- Vegetables

- Frozen pasta

- Frozen vegetables

- Fresh pasta

- Dry product

- Powder product

- Liquid product

- Creamy liquids

- Chemical products

Filling application:

- Combination weigher

- Linear weigher

- Cup measuring device

- Auger filler

- Liquide filler (pneumatic)(servo)

Film Width – 6” to 20.5”

Bag Size – L * W (2.25” ~ 13.75”) * (3” ~ 10”)

Max Speed – 70 Bags/min

Power – 208~240V 1phase 60Hz 3.5KW

HMI – 7” or 9.7″ HMI Touch Screen

Drive System – 1 or 2 Servo Motors

Gross Weight – 1100LB

V3000 Series Vertical Form Fill and Seal (VFFS) Machines

BESSEN V3000 Series Vertical Form Fill & Seal (VFFS) Machines: Technology for Flexible and Efficient Bagging

The BESSEN V3000 Series Vertical Form Fill & Seal (VFFS) Machines offer advanced packaging solutions designed to meet diverse bagging requirements. With the ability to handle a wide range of bag types, sizes, shapes, and styles, the 3000 Series delivers exceptional versatility and customization for industries such as food packaging, pharmaceuticals, and consumer goods.

Intuitive Operation:

Bessen’s 3000 Series machines are equipped with a user-friendly interface that simplifies operation and enhances efficiency. Features include:

- Effortless program adjustments

- The ability to save and load up to 30 preset parameters

- Seamless transitions between various bag styles and products

These capabilities reduce changeover times and maximize production efficiency, making the V3000 Series ideal for high-volume packaging operations.

Quality Assurance:

Leveraging innovative plastic tracing technology, the V3000 Series ensures precise film movement control, resulting in consistently superior seals, including the center seal. This guarantees high-quality, reliable packaging with every production cycle.

Why Choose Bessen V3000 Series?

The BESSEN VFFS 3000 Series Machines provide flexible and efficient solutions for automatic bagging, whether you need to package pillow bags, gusset bags, 4-way seal bags, or flat-bottom bags. These machines are tailored to meet your specific packaging needs, offering unmatched reliability and performance.

Optimal Fetchers

- Gusset device

- Hanging hall punching device

- Gas flashing

- Air removal

- Air expelling

- PE film sealing

- Seal cooling

- Vibrating

- Easy tear

- Bag support

Application

- Vegetables

- Frozen pasta

- Frozen vegetables

- Fresh pasta

- Dry product

- Powder product

- Liquid product

- Creamy liquids

- Chemical products

Filling application:

- Combination weigher

- Linear weigher

- Cup measuring device

- Auger filler

- Liquide filler (pneumatic)(servo)

Film Width – 6” to 20.5”

Bag Size – L * W (2.25” ~ 13.75”) * (3” ~ 10”)

Max Speed – 70 Bags/min

Power – 208~240V 1phase 60Hz 3.5KW

HMI – 7” or 9.7″ HMI Touch Screen

Drive System – 1 or 2 Servo Motors

Gross Weight – 1100LB