Smart Filling Lines

Bessen Filling lines equipment is some of the most versatile machine on the marketBESSEN Filling Lines Equipment is designed to provide advanced, efficient, and reliable solutions for a wide range of packaging applications. From liquid filling machines to volumetric filling systems, our equipment offers precise and consistent performance, tailored to meet the needs of industries such as food and beverage, pharmaceuticals, cosmetics, and industrial goods.

With fully customizable options, BESSEN filling lines ensure seamless integration into your production process, optimizing packaging efficiency and enhancing product quality. Whether you need high-speed servo-driven filling machines or durable pneumatic filling systems, we deliver solutions that adapt to your specific operational requirements.

Explore BESSEN’s innovative filling line equipment and discover how we can help you streamline your production line while maintaining the highest standards of accuracy and reliability.

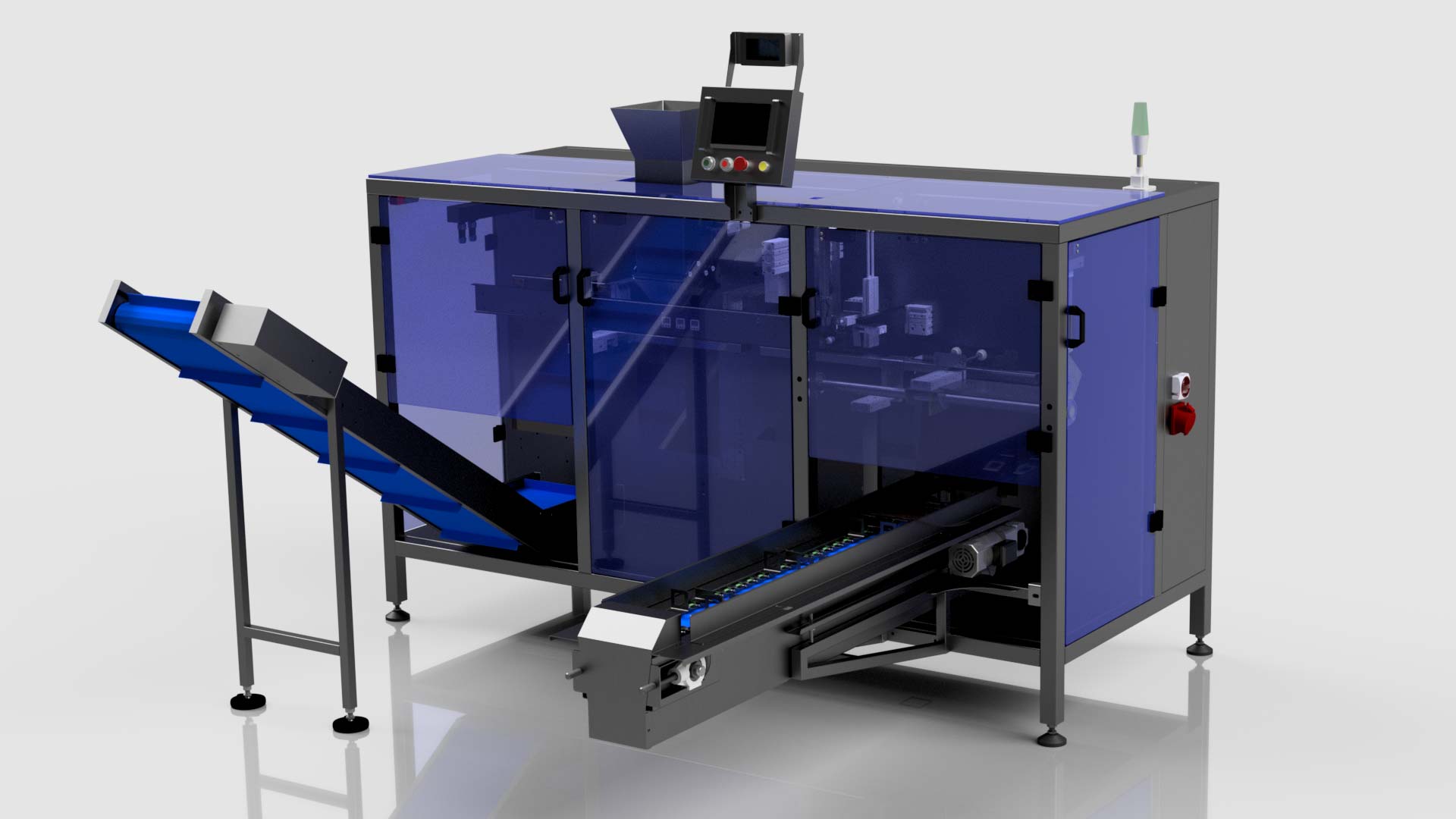

Smart Fill 4-12

BESSEN SMART FILL 4-12

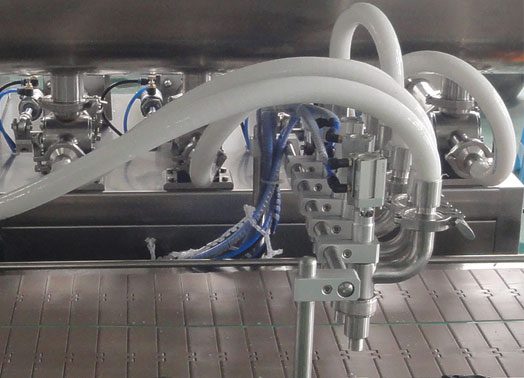

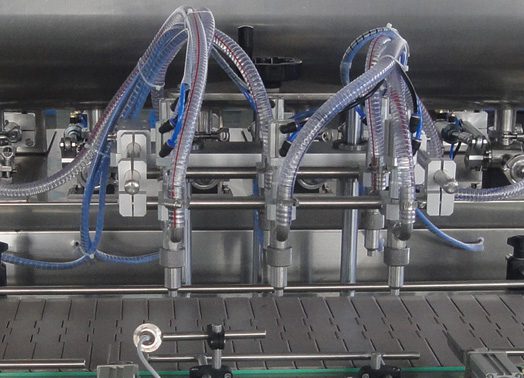

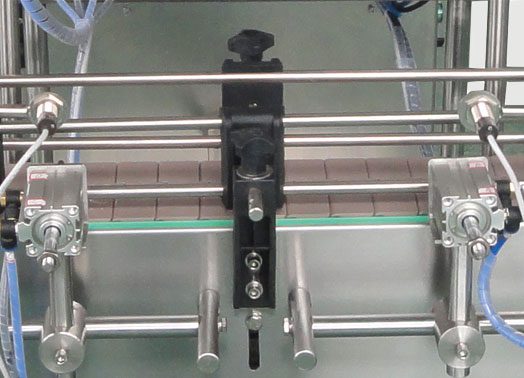

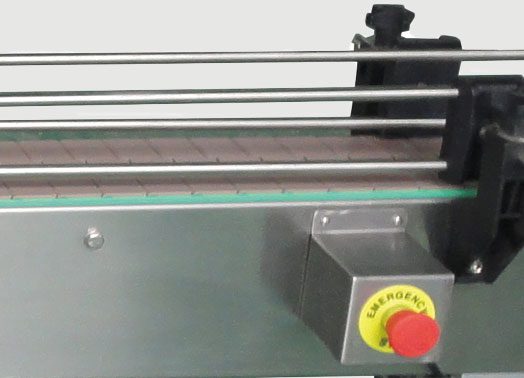

Our Smart Fill Linear Filling Lines are designed with advanced failure-safe features, accommodating various bottle types and operating conditions. These liquid filling machines handle products of varying viscosities, from thin liquids to thick materials, with customizable bottle sizes for maximum flexibility and efficiency.

Advanced Features for Optimal Performance:

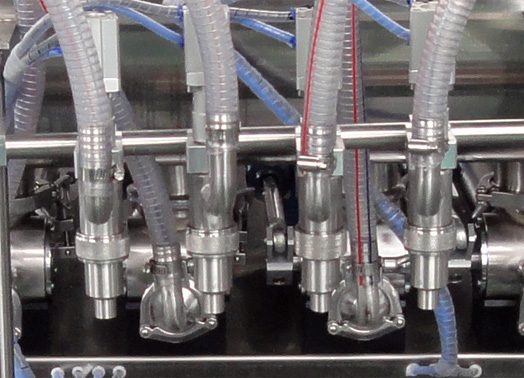

- Volumetric Filling: Ensures precise control over product quantities.

- Pneumatic and Servo Models:

- Pneumatic systems: Reliable and cost-effective.

- Servo-driven machines: High accuracy with adjustable speeds to reduce foaming and programmable recipes for customization.

Specifications:

- Adjustable Nozzles: Customizable for different bottle sizes and product types.

- HMI Control: Easily manage filling timing, spacing, and conveyor speed.

- Flexible Speeds: Adaptable filling speed to suit product characteristics.

- Customizable Tanks and Hoses: Tailored to meet specific requirements.

Options:

- Nozzle Count: Choose between 4 to 12 nozzles.

- Nozzle Types: Select nozzle types for various materials.

- Hose Customization: Tailored hoses for unique operational needs.

Ideal for food and beverage, pharmaceutical, and cosmetic industries, our filling lines ensure precise filling and enhanced packaging efficiency.

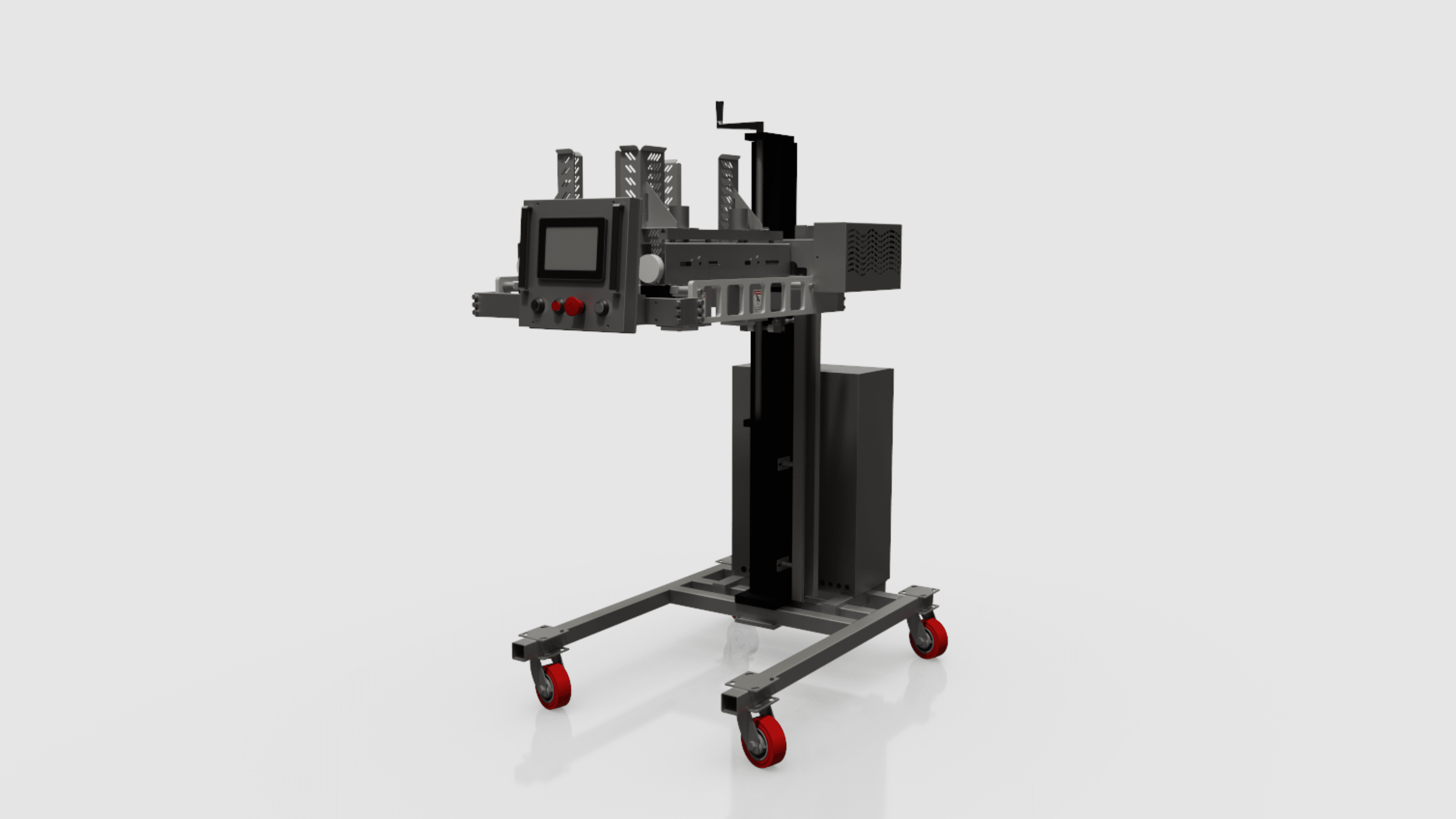

Simple Fill 400

Simple Fill 400

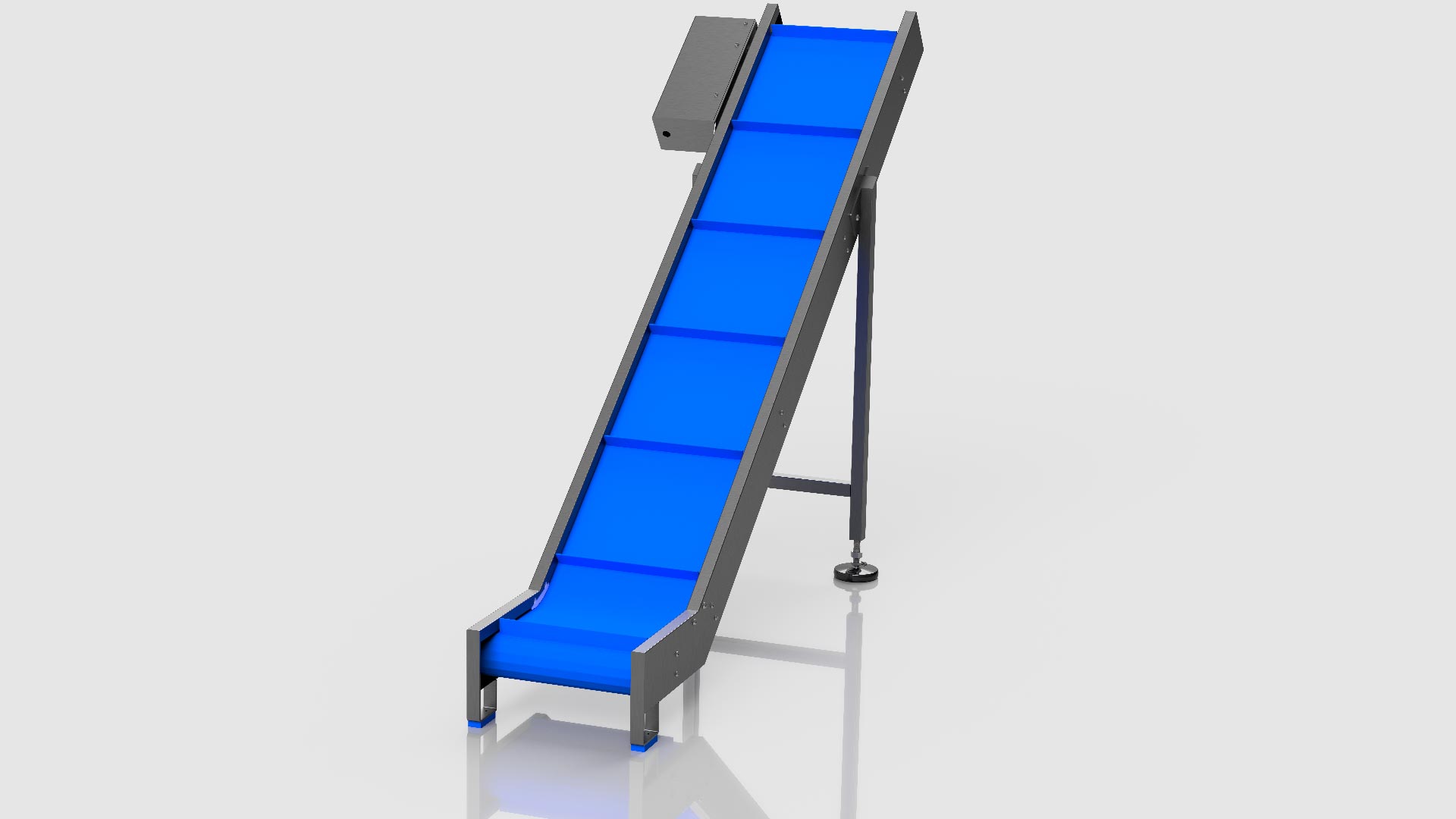

The Smart Fill 400 Line is an entry-level filling machine, designed for small-scale production. Easy to use and versatile, this model handles both liquid and viscous products with precision and reliability. Perfect for businesses with lower production volumes, the Smart Fill 400 Line can be customized and expanded to meet evolving needs.

Key Options:

- Nozzle Count: Choose between 4 to 10 nozzles based on production requirements.

- Nozzle Types: Select the appropriate nozzle type for your specific product material.

- Customizable Hoses: Different hose materials can be tailored to customer specifications for optimal performance.

Ideal for industries like food and beverage, pharmaceuticals, and cosmetics, the Smart Fill 400 Line delivers flexibility and efficiency, making it a valuable addition to your production line.

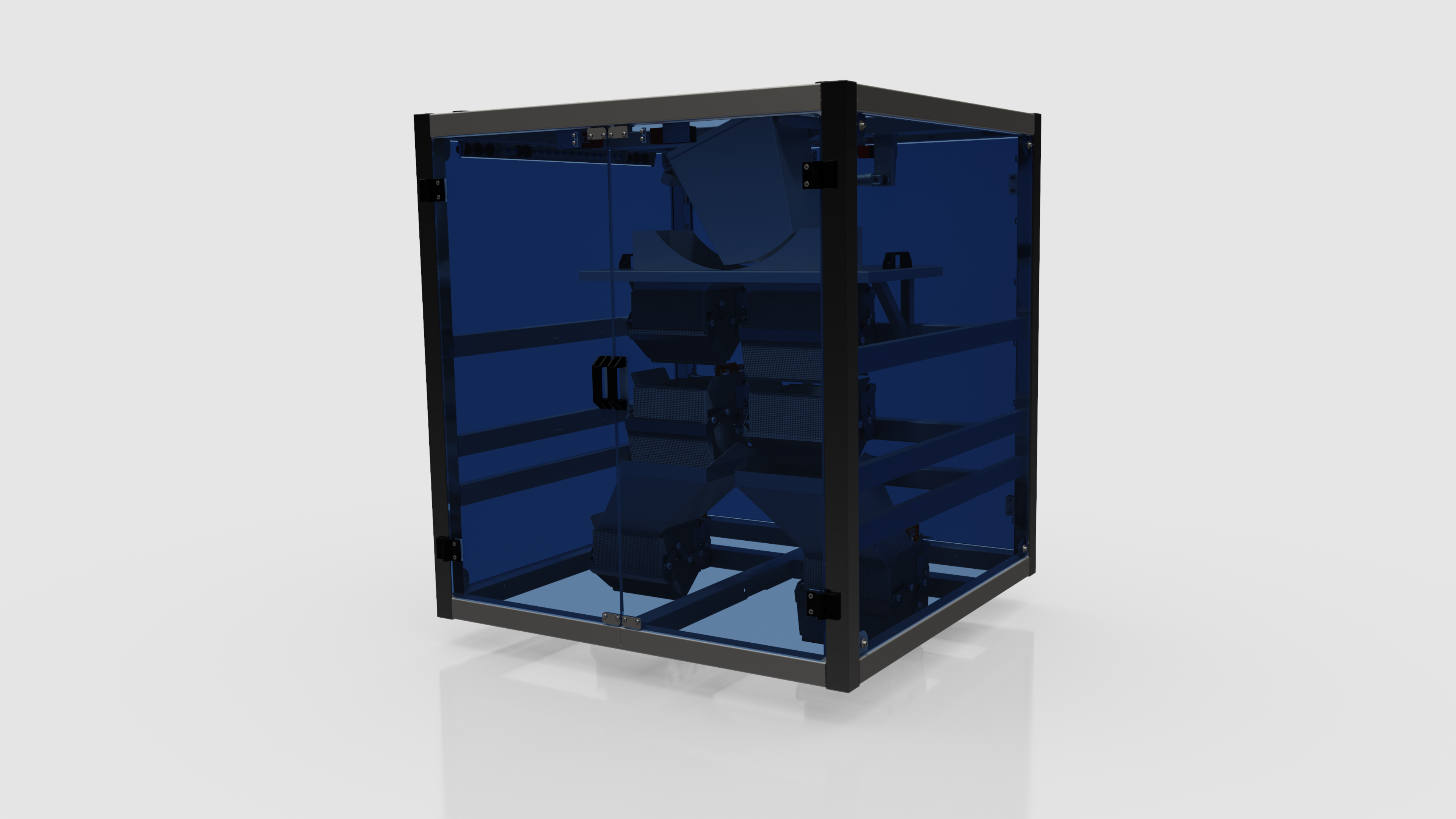

Easy Cup Fill 200-800

Simple Cup Fill 200-800

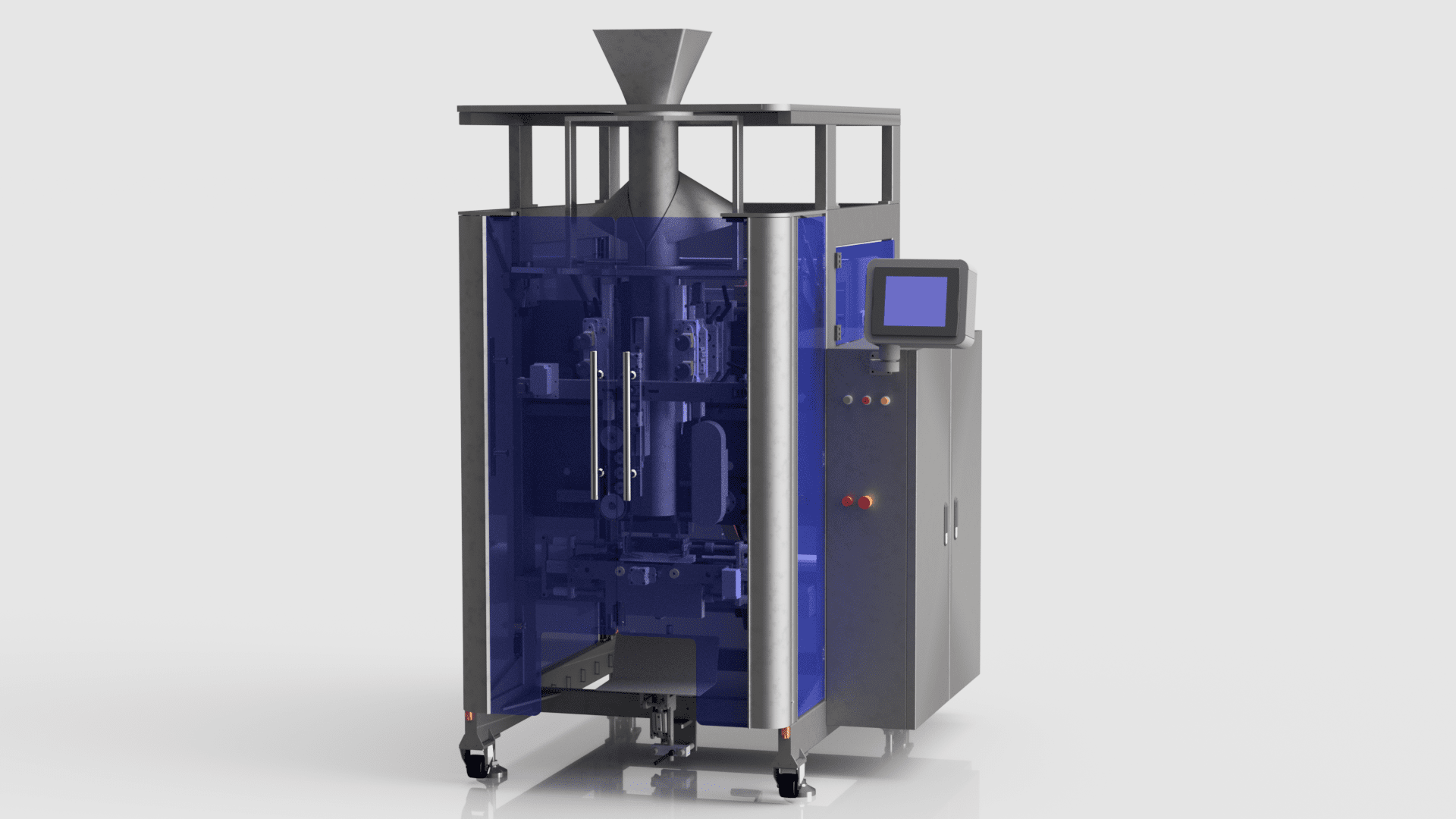

The Easy Cup Fill 200-800 is a versatile and efficient solution for precise cup-based packaging in industries such as food and beverage, dairy, and snack production. Designed for ease of use and reliability, this machine handles a wide range of product types, from liquids to semi-viscous and solid products, with customizable settings to meet your specific packaging needs.

Key Options:

- Adjustable Filling Volume: Accommodates product quantities from 200 to 800 ml per cup.

- Product Compatibility: Supports a variety of products, including liquids, semi-viscous, and solid materials.

- Customizable Cup Sizes: Works with different cup dimensions based on production requirements.

- Multi-Lane Filling: Optional multi-lane configurations for increased production capacity.

- Hygienic Design: Easy-to-clean components for maintaining strict hygiene standards.

- Film Sealing Integration: Includes optional sealing functionality for a complete cup packaging solution.

- Intuitive HMI Control: User-friendly touch screen interface for quick adjustments and efficient operation.

The Easy Cup Fill 200-800 is ideal for businesses seeking a compact, reliable, and flexible filling solution to enhance packaging efficiency and maintain product quality.