Denester Machines

Automated Tray Denester for High-Speed, Precise, and Hygienic Container Separation

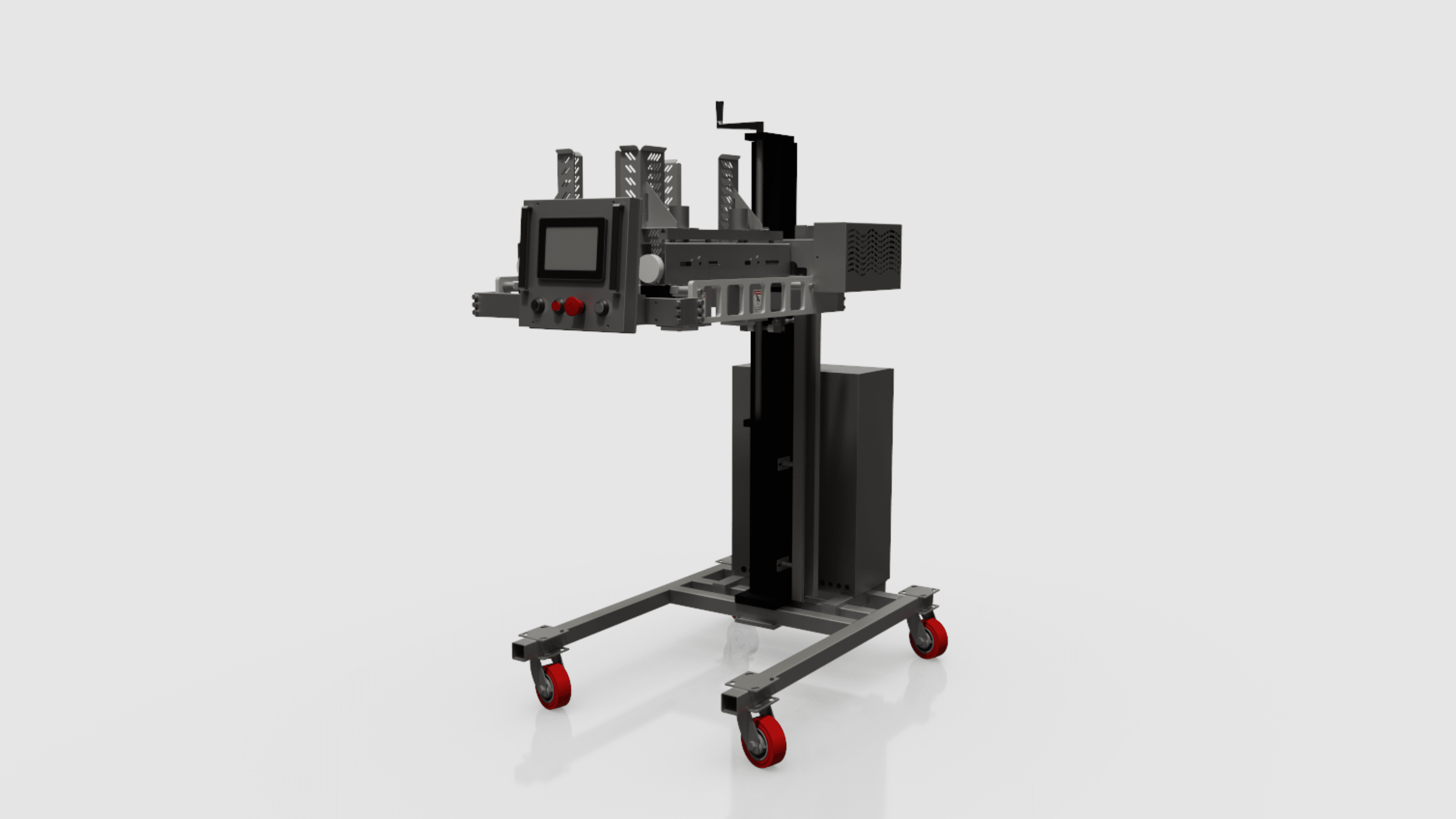

BESSEN Denester Machine

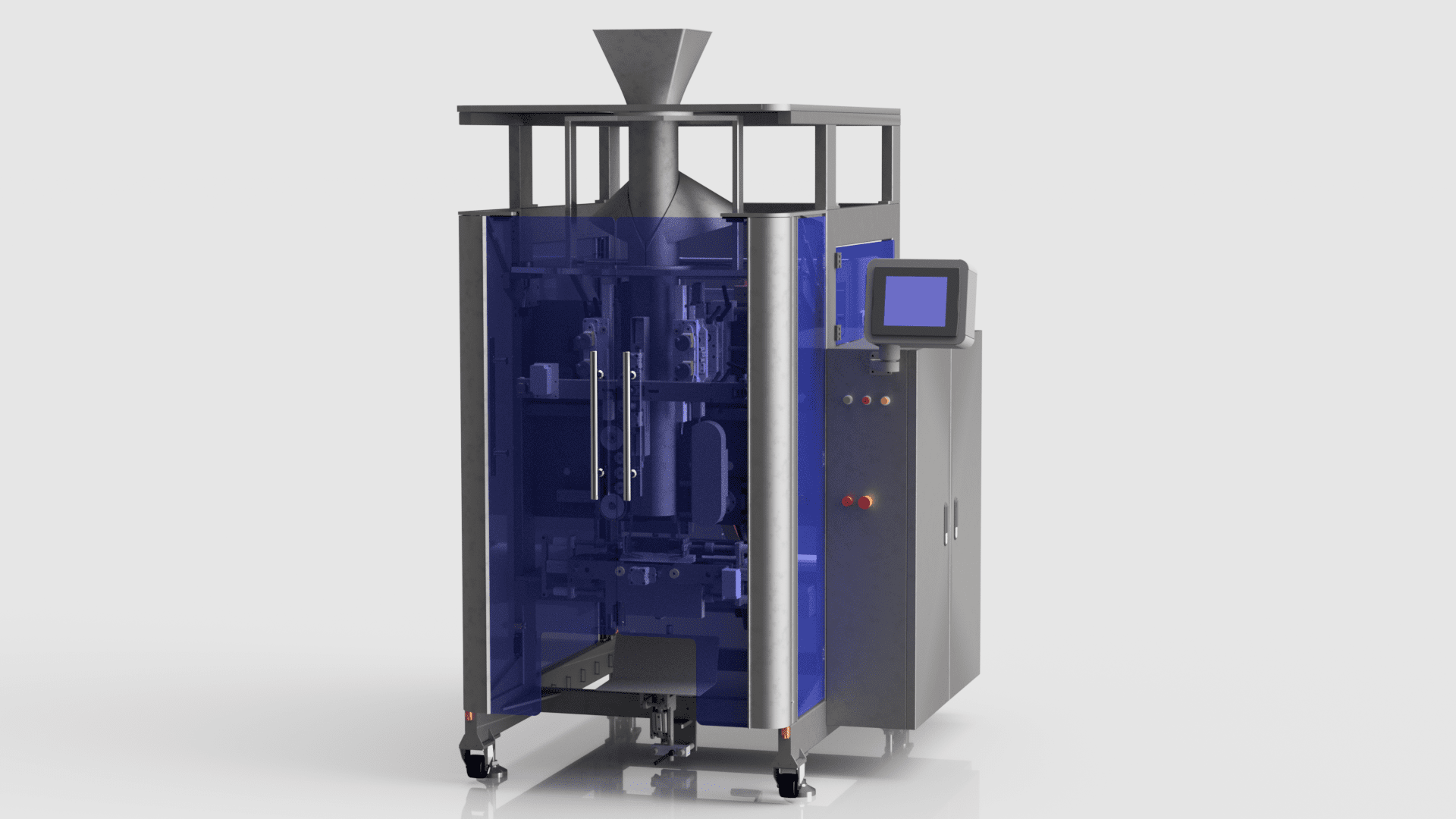

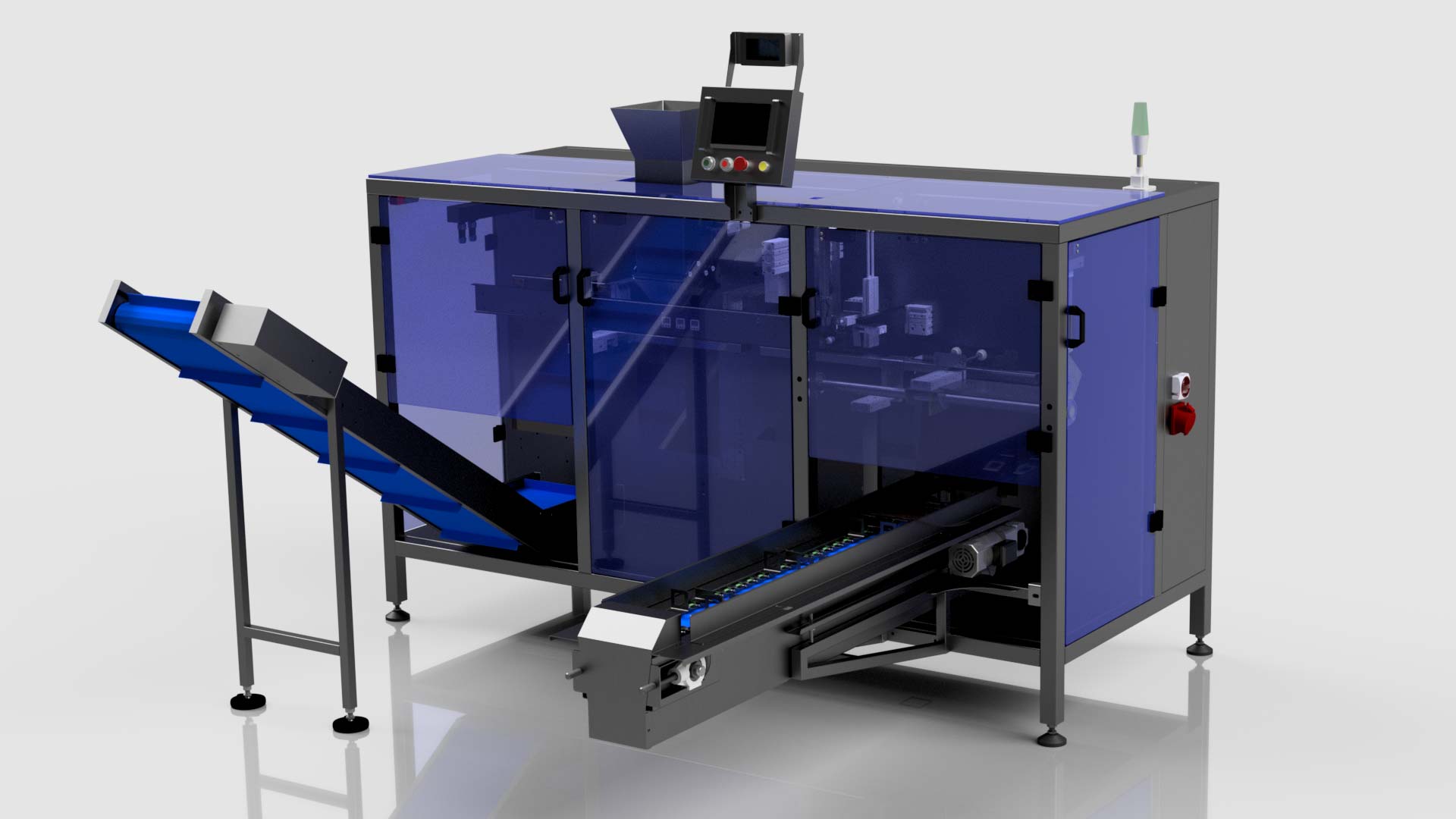

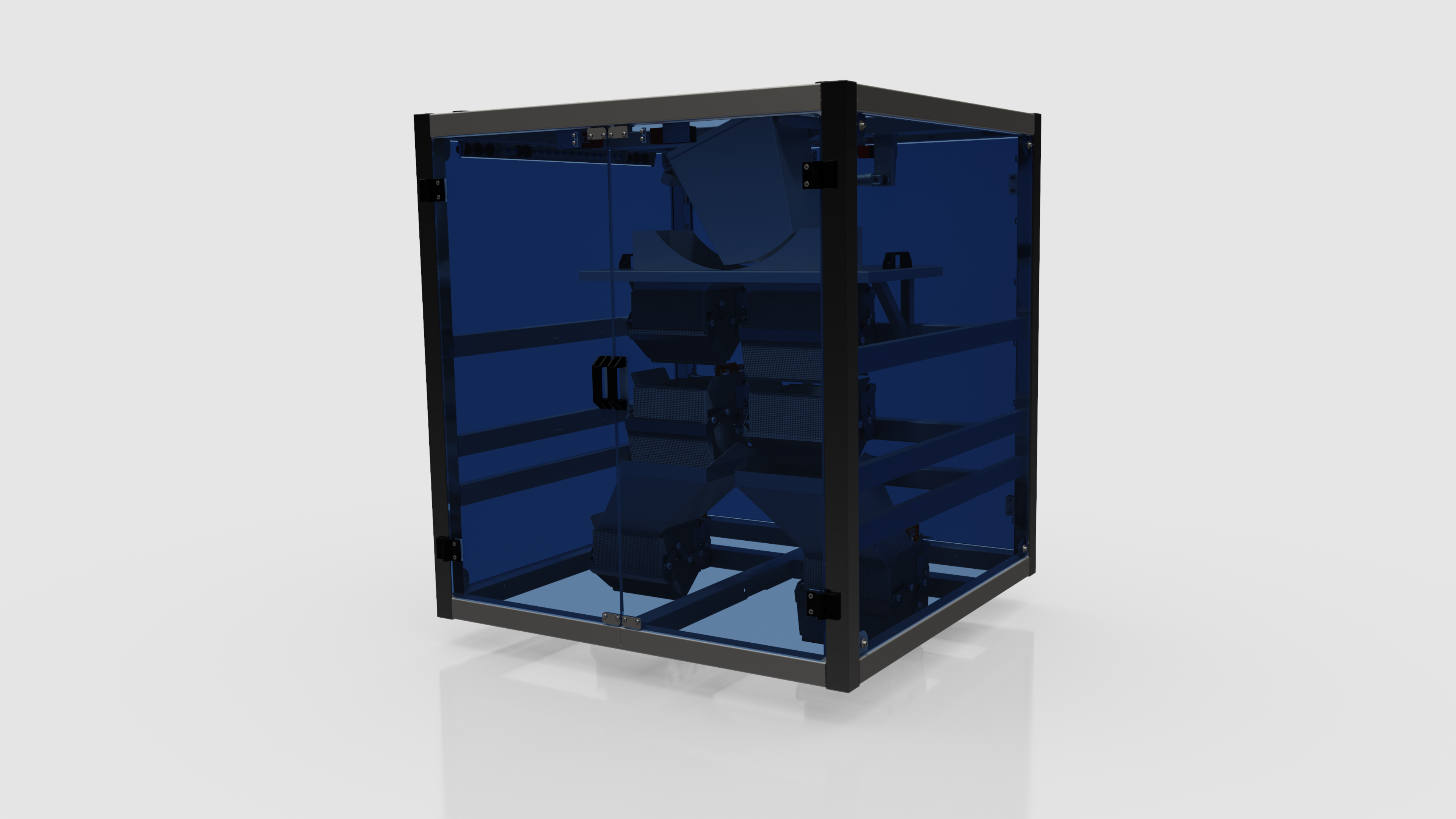

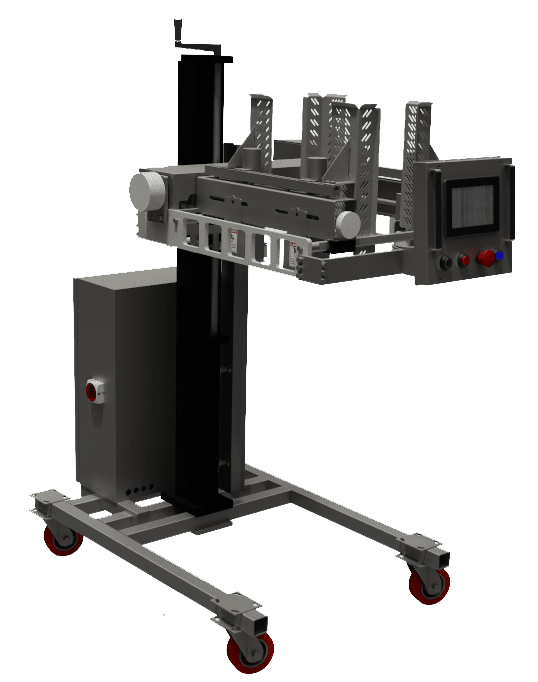

The BESSEN Denester is a compact, automated solution engineered to accurately and efficiently separate and place trays or containers onto packaging lines. Designed for high-speed operations, it integrates seamlessly with form-fill-seal machines, thermoformers, or manual loading stations to boost productivity and reduce labor costs.

With precision mechanics, food-safe materials, and a user-friendly control interface, the BESSEN Denester is ideal for ready meals, bakery trays, meat, or produce packaging applications where tray handling consistency is critical.

Key Features:

AUTOMATIC TRAY DISPENSING:

Reliably denests trays from a stack and places them onto conveyors or into molds at consistent intervals for seamless integration into downstream processes.

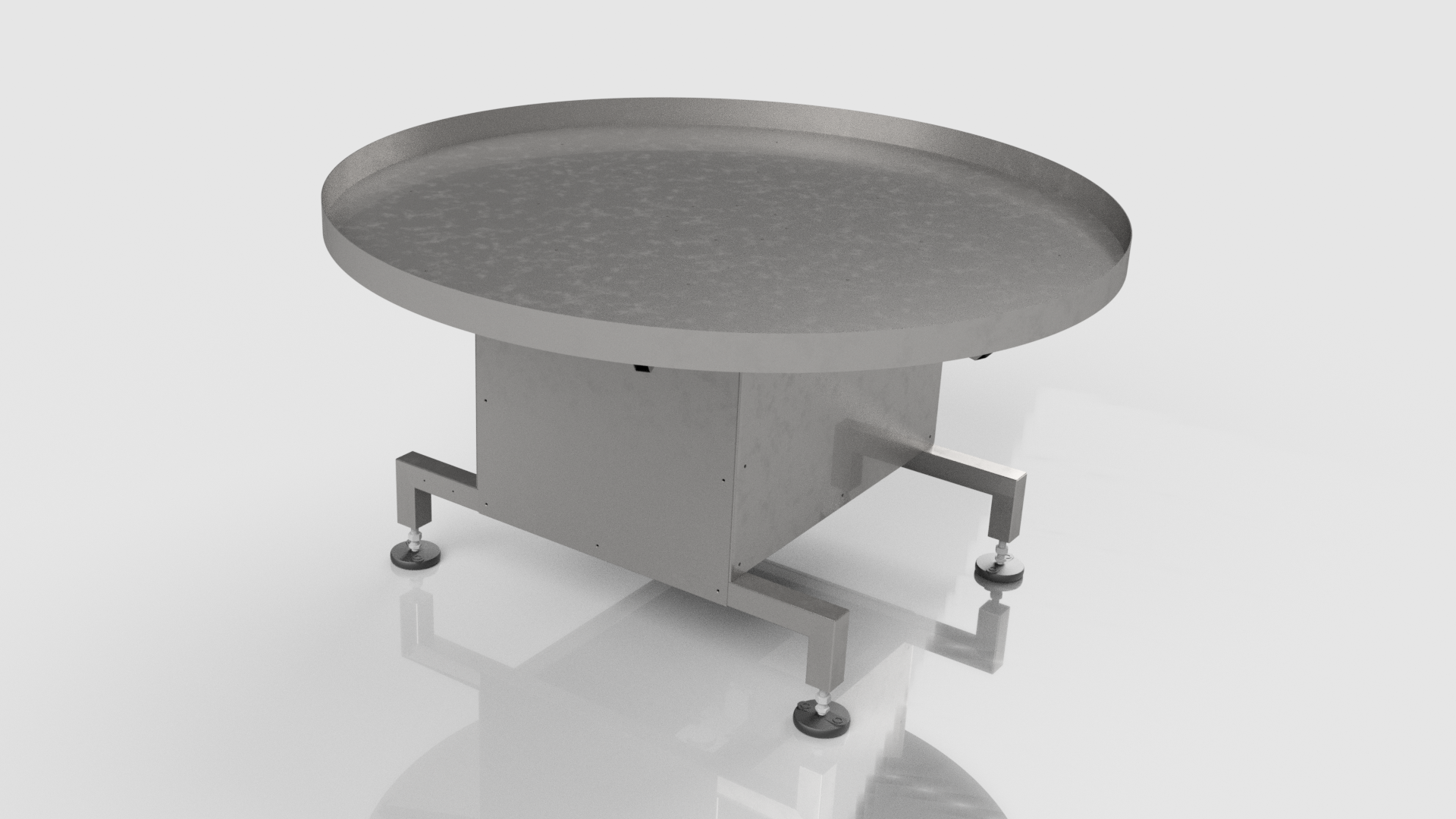

ADJUSTABLE MAGAZINE SYSTEM:

Compatible with various tray sizes and materials (plastic, paperboard, etc.) thanks to a flexible magazine design with quick-change adjustments.

HYGIENIC STAINLESS STEEL FRAME:

Constructed from durable, food-grade stainless steel to meet sanitary standards in food, pharma, and industrial packaging environments.

INTUITIVE TOUCHSCREEN CONTROLS:

Operators can set cycle speed, tray dimensions, and diagnostics through an integrated control panel with touchscreen display and emergency stop functions.

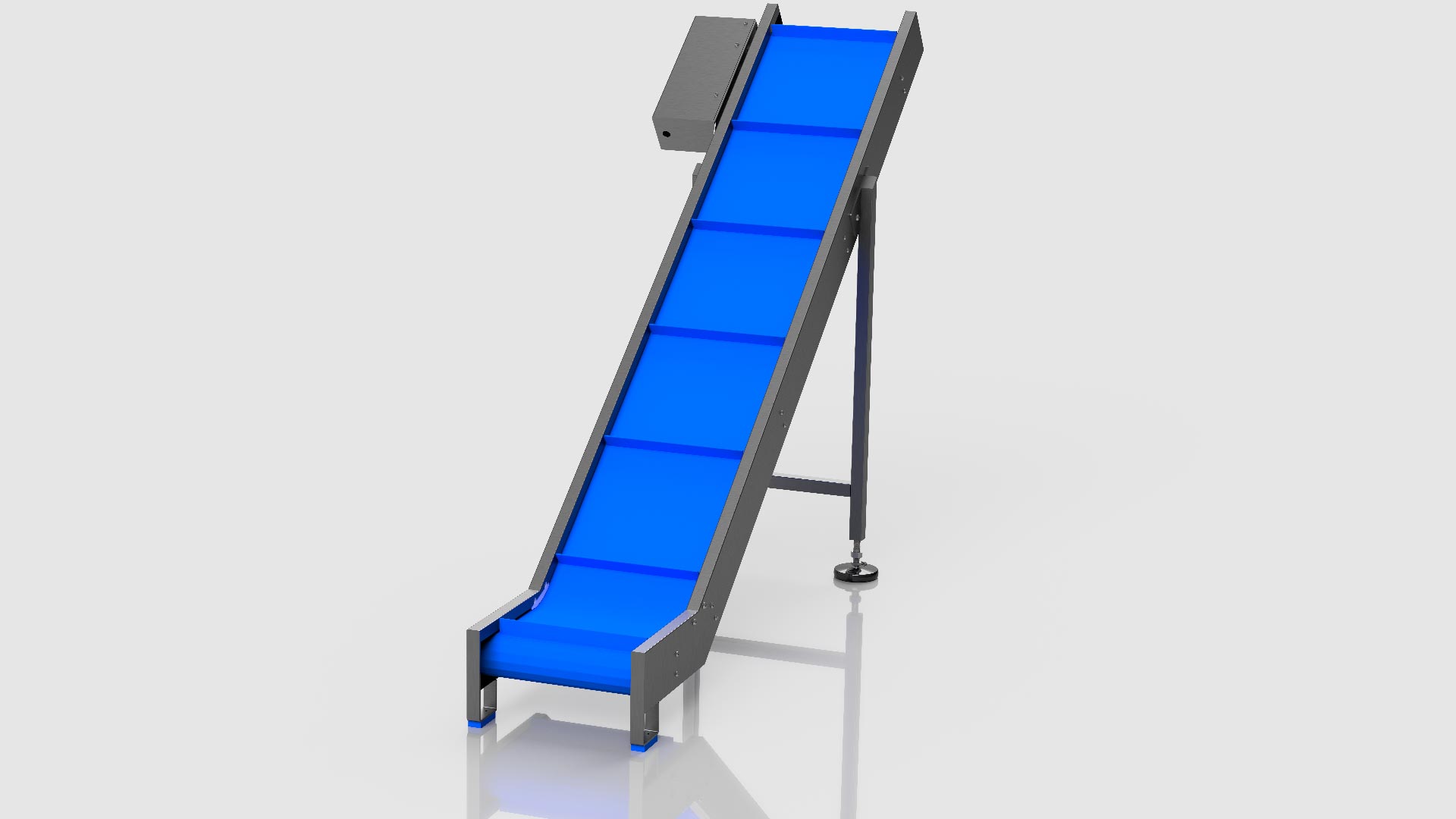

MOBILE AND SPACE-EFFICIENT:

Mounted on locking casters for easy repositioning within the production area, perfect for dynamic floorplans or multi-line operations.

MODULAR INTEGRATION:

Designed to pair with BESSEN filling, sealing, or labeling machines for a full automation line or used independently with existing equipment.

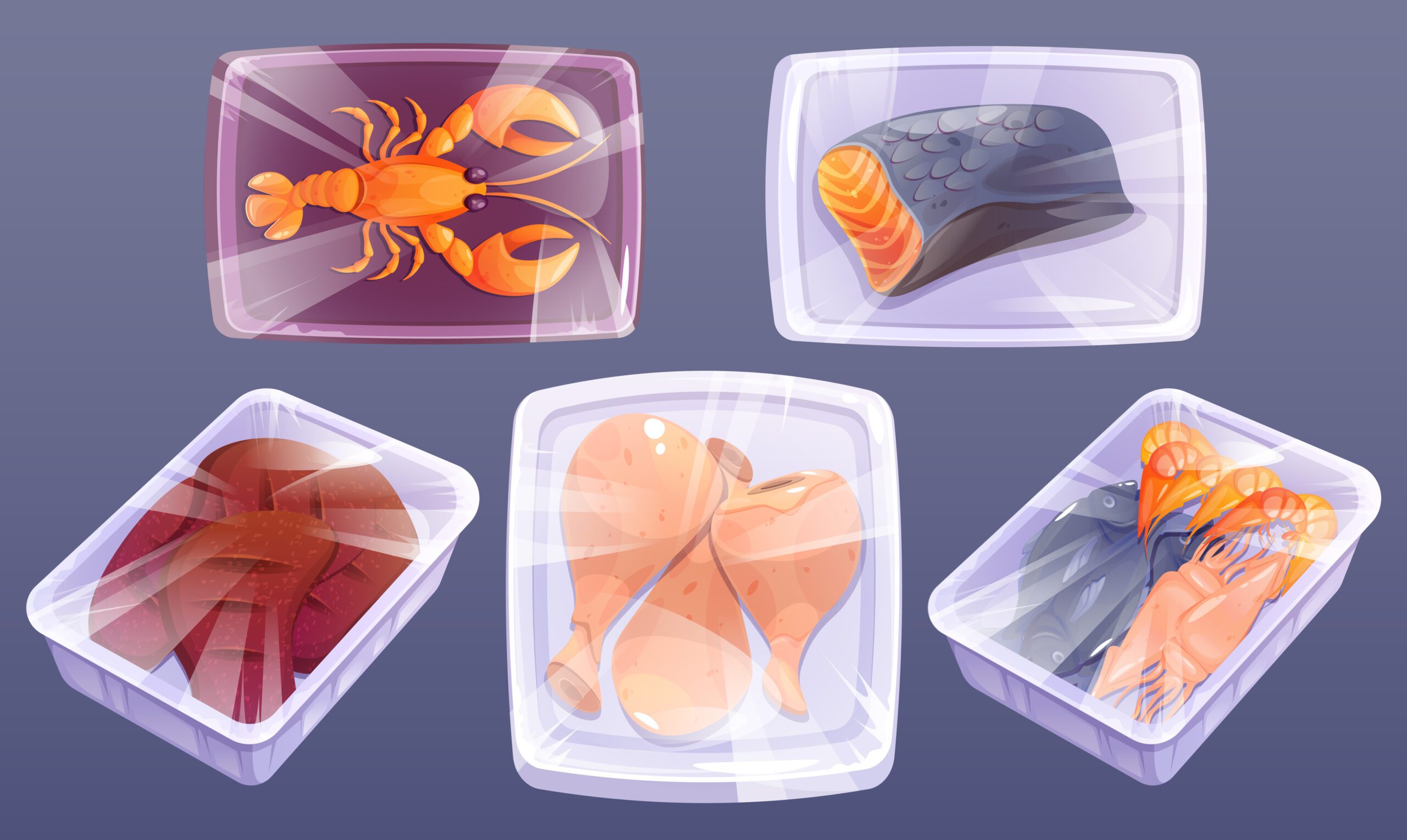

Ideal For:

READY MEALS AND FROZEN FOOD TRAY PACKAGING

MEAT, POULTRY, AND SEAFOOD APPLICATIONS

BAKERY AND CONFECTIONERY TRAY HANDLING

PRODUCE AND SALAD KITS

HIGH-VOLUME PACKAGING ENVIRONMENTS